Whether you’re an aspiring watchmaker, collector, or trying to give an old watch a new look, you’ve likely considered what it takes to make your own watch dial. While professional watch dial customization services can do the work for you, creating one yourself adds immeasurable personal value. Dial-making is an art that requires patience, determination, and a respect for precision. However, before you can bring your vision to life, you will need blank watch dials.

In most cases (and for most watch cases), blank watch dials can be purchased online, even in bulk from far-Eastern suppliers. Unfortunately, when I first began making my watches, I found that the size I needed wasn’t commonly available, and custom orders required committing to quantities I didn’t need. This led me to discover creative ways to produce my own dial blanks, accessible to a DIY watchmaker or hobbyist.

Cutting Your Watch Dial

If you are modifying an existing watch, you may find dial blanks available online for your specific make and model. However, depending on how many dials you want to make, it may be worthwhile to learn how to make your own blanks. For Strukwerk, Ambassador models use ⌀29.45mm and ⌀28.70mm dials, while the Mercury uses ⌀33.5mm dials, none of which are readily available at a low cost. To make dials in any shape I wanted, I purchased 0.4mm thick tinplate sheets (40 x 80 cm) for roughly $12 each. Tinplate consists of steel coated with a thin layer of tin to prevent oxidation. When making dials, it’s crucial to consider the height of the cannon pinion of your movement. The last thing you want is to create a beautiful dial that’s too thick for the watch hands to move smoothly.

Cutting the dial to shape requires precision, but keep in mind that you can always use a metal file to correct imperfections—and there will be some. I have successfully cut dials using three different methods.

Cutting Watch Dials By Hand

Time and patience are recurring themes in watchmaking and dial-making alike. Given the small thickness of the material, it can be cut with aviator shears or even a fine-tooth metal saw. Use a circular compass to draw the outline, and start cutting out your dial while aiming to minimize warping. Finally, refine the shape with a metal file. From my experience, it took about an hour to make watch dials this way, while I was making my first Ambassador watch.

Cutting Watch Dials with a CNC Machine

For greater precision, you can use a 3-axis CNC machine to cut your dial blanks. You’ll need access to the machine and a reliable way to clamp your sheet metal without warping it. CNC machines come in various formats, from large machines used for woodcutting projects to smaller, tabletop models.

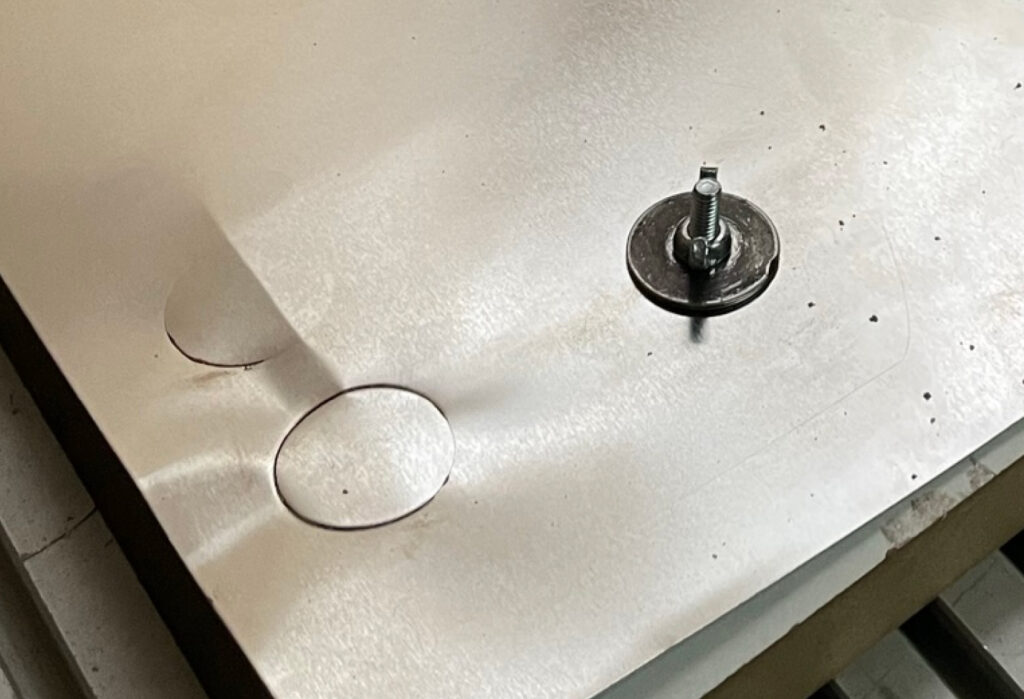

The main challenge I encountered with the CNC was securing the metal to a level work surface. The sheet needs to be fastened tightly enough to prevent the end mill from moving it, but this makes it difficult to remove the cut dial from the workplate. Another drawback is the noise. Operating a desktop CNC, like a Genmitsu 3018, can create enough noise to disturb your neighbors. However, it’s still a feasible solution if you need to create precisely cut dial blanks at a rate of multiple dials per hour.

Laser Cutting Watch Dial Blanks

Laser cutting is, by far, the best way to produce dial blanks. It’s fast and easy to learn, but requires access to industrial-grade equipment. Fortunately, my local maker space has a 1500-watt fiber laser, which allows me to produce over a hundred ready dial blanks per hour. With this equipment, we’ve also been able to cut dials from steel, aluminum, and brass. Depending on the scope of your project, you may want to use a higher-quality material than tin.

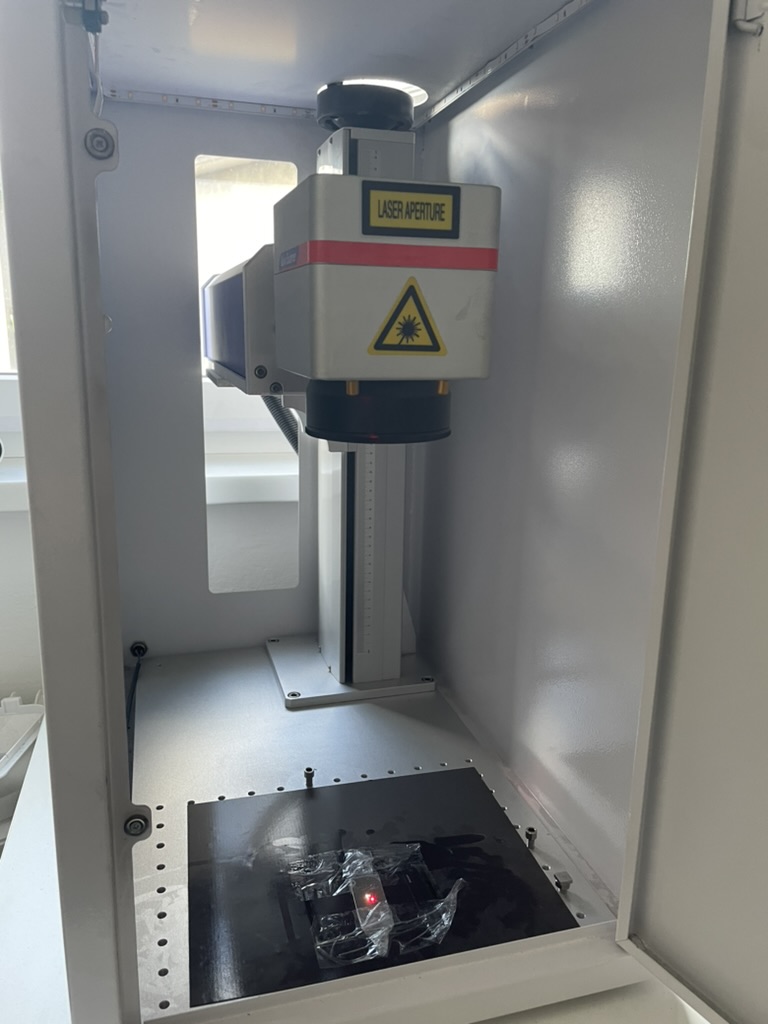

Raycus 30W Fiber Laser for Watch Dials

We used a 30-watt Raycus fiber laser for several months, testing it for making dials and other watch parts. Using the fiber laser, we could cut a blank dial for the Ambassador model in about an hour. We believe it’s possible to achieve this faster with improved job configuration. While the result was better than the CNC, it was slower—though considerably quieter. It was also able to cut 0.4mm steel discs. Ultimately, we regretted not opting for the 50W or 70W unit, which would have been more efficient.

Diode Lasers and CO2 Lasers for Dial Cutting

The answer to the question, “Can I use a CO2 laser or diode laser to cut watch dials?” is no, not if you’re working with metal. Metal cutting isn’t possible outside an industrial setting. However, CO2 lasers can be used for other dial-making purposes, such as engraving. Diode lasers also have applications in DIY watchmaking. Be cautious of fumes produced by lasers and do your research to determine whether cutting certain materials generates hazardous smoke or waste.

Final Thoughts on Making Custom Watch Dial Blanks

Creating custom watch dials is an art that blends technical skill with creative vision. Whether you choose to cut dials by hand, use a CNC machine, or opt for laser cutting, each method has its unique benefits and challenges. Hand-cutting offers a personal, time-tested approach but requires patience. CNC machines provide precision but come with the complexities of setup and noise. Laser cutting, especially with fiber lasers, is the most efficient and precise option, though access to equipment can be a limiting factor.

Establishing a reliable method for producing dial blanks opens the door to experimentation and creativity. By having a steady supply of blanks, you can fine-tune your designs, test different materials, and perfect details like hole placements and finishing options. While large-scale manufacturers rely on precise, repeatable processes, DIY watchmakers often experience what I call “happy accidents,” where experimentation leads to unexpectedly successful results. However, balancing creativity with an iterative process allows you to grow as a craftsman, building upon each success and learning from every challenge.

In the end, making your own dials not only enhances your watch’s aesthetic but also deepens your connection to the craft. The process is rewarding, providing you with both practical skills and the satisfaction of creating something uniquely your own. Whether you’re making one dial or a hundred, each step is part of the journey toward mastering the art of watchmaking.